Tank Car Class and Specification Markings

Tank Car Class and Specification MarkingsThe tank car DOT number designates the exact specification to which it was designed. DOT class stencils are located on the side of the tank car at the BL and AR locations just above the tank test date and below the product stencil, if one is applied.

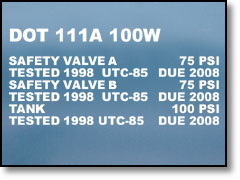

This is a DOT 111A100 W. This stencil indicates the following:

DOT - Designates the Department of Transportation which is the authorizing agency.

111 - Designates a specific design. There are over ninety designs.

A - Equipped with top and bottom shelf couplers.

100 - Is the Hydrostatic and / or maximum design pressure of this unit.

W - Designates this tank is made of a welded construction.

Additional tank car specifications which could be found in this area are shown on the tank car below. The specifications that are present vary depending on the type of tank car. A detailed description of each item follows the picture.

Safety Valves

Safety Valves